Read more about Agri Automation? Enter your e-mail address here and you will receive the PDF.

Powerful spring-applied tooth brake as an alternative to the conventional permanent magnet brake

Safety component with "teeth"

The rapidly growing robotics market, as well as other demanding industries, requires drive components with increasingly higher power densities and safety functions. In order to meet these challenges in a targeted manner, Mönninghoff offers a particularly space-saving yet very powerful electromagnetic spring-applied tooth brake as the perfect alternative to conventional permanent magnetic brakes.

Wherever friction brakes offer high positioning accuracy, but quickly reach their limits due to friction torque transmission, the gear brake from Mönninghoff can be used. New production processes provide a gear transmission that can position and fix the brake in very fine steps. The positive torque transmission offers significantly higher torques in the range up to 6000 Nm. Especially in the field of robotics or servo technology, these brakes are increasingly used with their small space requirements, high power density and maximum safety requirements.

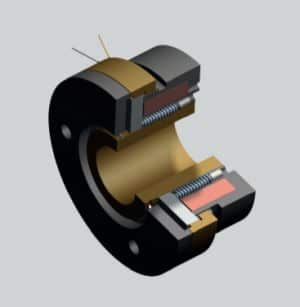

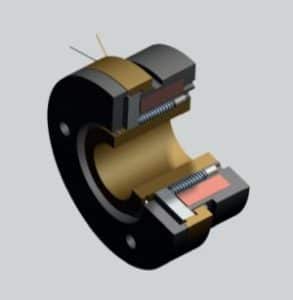

Function and structure

The spring-applied tooth brake is normally held closed by the pressure springs which bring the two toothed rings into engagement. The torque is transmitted backlash-free and slip-free via the guide toothing. The brake is released by means of an electromagnet which counteracts the spring force and thus releases the brake. This allows the brake to act as a fail-safe product. In all its functions, this spring-applied tooth brake can also be designed as a clutch.

The right brake for every requirement

Mönninghoff develops a wide range of clutches and brakes for special requirements of each industry and every application. For example, the brake can be released pneumatically or actuated electrically. It is also conceivable to adjust them with a defined spring force. In addition, the individual design of the gearing geometry makes it possible to respond to every special application with a special solution. There is also the possibility to design the brake “bistable”. This means that in the event of a power failure, the last prevailing switching state is guaranteed to be maintained. This bistable version is particularly well accepted in mobile applications, as energy is only required to change the switching state, making it very energy-saving.

Download here the Brochure of Mönninghoff’s Electromagnetic spring-applied tooth brake.