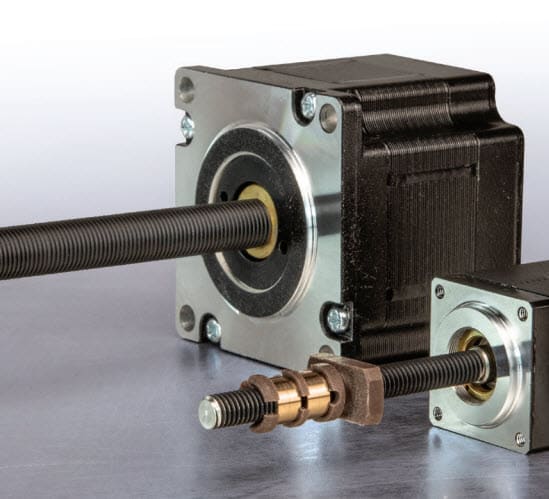

PBC Linear: Lead Screw Assemblies

As today’s technological capabilities have become more sophisticated, the working parts within machine systems require greater performance. That need for more precise linear motion has driven PBC Linear to work on an integrated lead system, with precision focus on three points including the screw, the nut and the motor.

More sophisticated lead screw

The manufacturing of a lead screw requires a complex manufacturing process. After the initial grind-down of raw materials, PBC Linear utilizes a German CNC roll threader that incorporates precision process adjustments and controls while employing automated in-feed and outfeed features. This provides consistency over the full length of the screw stock.

Next in line is an automated straightening process. Because of this, PBC Linear can minimize runout and its potential negative effects. There is also a PTFE coating on the lead screws, that increases the quality of the finish, including the elimination of surface pitting of flaking over time.

Innovative anti-backlash nut

This design utilizes a spring that applies uniform radial pressure to the nut at all stages of the motion profile. It boasts:

- Superior backlash compensation

- Consistent preload over life

- Two to four times better performance than traditional designs

- Self-lubricated feature

- Simple two-piece design

Incorporation of high-end, lead screw motors along with machined end journals

The final addition to the lead screw assembly is the drive system. The lead screw is matched to a hollow shaft motor and then precision mounted. The motor’s hollow shaft concentricity minimizes runout to values less than 0.003 inches. The larger bearings of the drive system increase thrust capacity and add longer life.

More comprehensive metrology at each stage of lead screw production

PBC Linear dedicates two separate tests labs that are focused on establishing high performance characteristics within their product line. One lab is used for load and life and the other lab is sound-proofed, which allows technicians to analyze product noise levels.