Kom naar de Eltrex Motion Innovation Day 2025

Ben jij actief in de wereld van robotica of aandrijftechniek? Dan mag je dit event van Eltrex Motion niet missen! Toonaangevende experts nemen je mee in de nieuwste ontwikkelingen, slimme toepassingen en baanbrekende innovaties op het gebied van motion control.

Wat kun je verwachten?

7 Oktober 2025 | 9:30-17:00 | High Tech Campus | Eindhoven

- Inspirerende presentaties van vakexperts

- Antwoord op jouw technische vragen direct van onze engineers

- Praktijkgerichte inzichten en live demo’s

- Netwerkmogelijkheden en fun met collega-professionals

Let op! In verband met de aanwezigheid van internationale vakexperts zal het event Engelstalig zijn.

Agenda

- 9:30 - Welkom & registraties

- 10:00 - Expert presentaties, demo's & netwerken

- 12.15 - Lunch, demo's & netwerken

- 13.00 - Expert presentaties, demo's & netwerken

- 15:00 - Afronding & belangrijkste inzichten

- 15:30 - Gezellig evenement, drankjes & netwerken

- 17:00 - Einde

De volgende samenvattingen belichten de toepassingen en innovaties uit de praktijk die aan bod zullen komen.

HOGERE VERMOGENSDICHTHEID: OP WEG NAAR SLIMMERE, MEER GEÏNTEGREERDE MOTION SYSTEMEN

Presentatie door Simone Pedrazzi, Applications Engineering Manager bij Elmo Motion Control

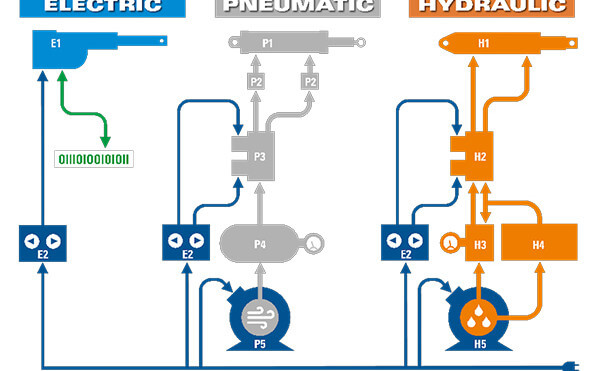

Bij motion control draait het niet meer alleen om zoveel mogelijk vermogen leveren, maar om slimmer presteren: hogere vermogensdichtheid in steeds compactere, efficiëntere en intelligentere systemen.

Tijdens deze presentatie ontdek je hoe de nieuwste halfgeleidertechnologieën en slimme oplossingen voor thermisch beheer de prestaties van motoraandrijvingen naar een hoger niveau tillen. Je ziet hoe deze innovaties zorgen voor snellere respons, lager energieverbruik en betrouwbare prestaties – precies wat moderne automatiseringsomgevingen vragen.

Laat je inspireren en krijg concrete ideeën om jouw systemen klaar te maken voor de toekomst.

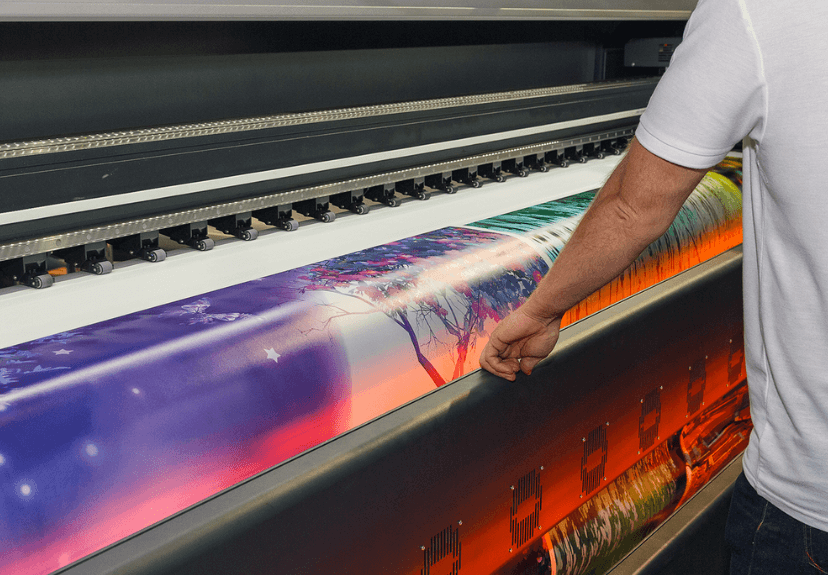

IMPULSE PRINTING: MICRO-ELECTRONICA PRODUCTIE MET HIGH-SPEED, HIGH EFFICIENCY MOTION CONTROL

Presentatie door Fabien Bruning, Co-Founder & CTO, FononTech

Geavanceerde chip-packaging met FononTech’s Impulse Printing technologie. Rapid Parallel Heating zorgt voor de snelste en meest accurate 3D printtechniek voor chips op de markt. Real-time precisie motion control maakt dit mogelijk en resulteert in een superflexibel en schaalbaar printplatform.

Achter deze innovatie schuilt realtime, nauwkeurige motion control die zorgt voor perfecte overlay-prestaties. Zo ontstaat een flexibel en schaalbaar platform waarmee fabrikanten sneller, nauwkeuriger én kostenefficiënter kunnen produceren. Ontdek tijdens deze sessie hoe deze technologie de toekomst van high-tech productie vormgeeft – en wat dat voor jouw processen kan betekenen.

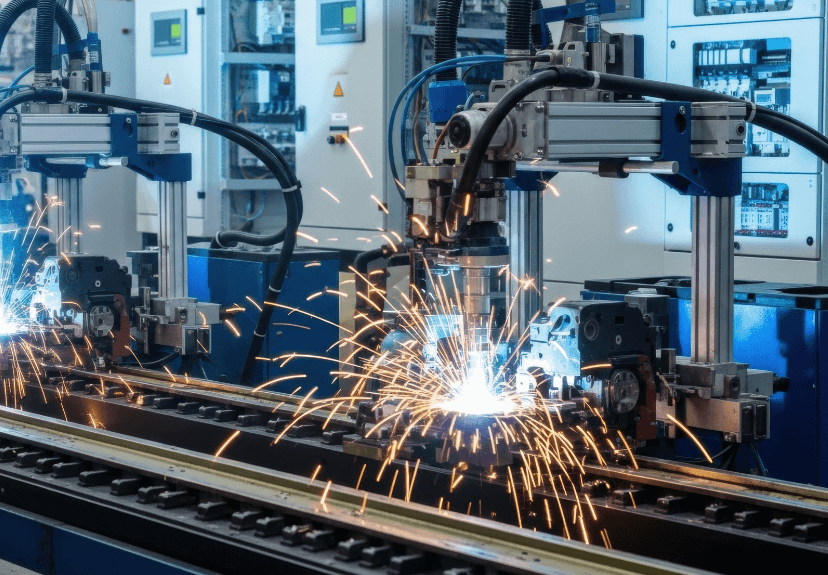

COMPACT MOTION CONTROL DESIGN MET ILSM MOTOREN

Presentatie door Motor Power Company

De sterk gereduceerde mechanische complexiteit van de ILSM-technologie (Independent Linear Synchronous Motor) levert ongekende prestaties in een compact design. Dankzij directe aandrijving behoren riemen, schroeven en tandwielen tot het verleden. Het resultaat? Razendsnelle, uiterst precieze en volledig spelingvrije bewegingen, minder mechanische complexiteit én lagere onderhoudskosten.

Maak naast de interessante presentatie ook kennis met de multipoolarchitectuur; hierdoor ontwerp je compacter dan ooit, zonder concessies te doen aan vermogen, efficiëntie of snelheid. Tijdens het event laten we je een 10-polige servomotor zien die maar liefst 30% kleiner is dan eerdere modellen – perfect voor toepassingen waar elke millimeter telt.

FUNCTIONAL SAFETY, EEN STRUCTURELE VERSCHUIVING IN SYSTEEMONTWERP

Presentatie door Simone Pedrazzi, Applications Engineering Manager bij Elmo Motion Control

Automatiseringssystemen worden steeds complexer – en functionele veiligheid is daarbij geen luxe meer, maar een essentieel onderdeel van het ontwerp. Door veiligheidsfuncties direct in de aandrijftechnologie te integreren, verandert de hele aanpak: van losse, geïsoleerde modules naar een naadloos, veiligheidsgeïntegreerd platform.

Tijdens deze presentatie ontdek je hoe veiligheid op aandrijfniveau het systeemontwerp vernieuwt en zorgt voor een hechte samenwerking tussen beweging, besturing en veiligheid. Zo ontstaat een automatiseringsomgeving die robuuster is, makkelijker te onderhouden en optimaal voorbereid op samenwerking tussen mens en machine.

Eltrex Motion Innovation Day 2025. Mis het niet!

Ben je nog niet aangemeld? Meld je aan via onderstaande button!

Onze engineers hopen je op 7 oktober persoonlijk te mogen verwelkomen!

Neem gerust contact met ons op. Dat kan telefonisch via +31 (0)76 789 00 30 of +32 (0)3 328 07 60. U kunt ook het contactformulier invullen. Wij nemen uw vraag zo snel mogelijk in behandeling.