Join the Eltrex Motion Innovation Day 2025

Are you active in the world of robotics or motion control? Then you do not want to miss this event by Eltrex Motion! Leading experts will guide you through the latest developments, smart applications, and groundbreaking innovations in the field of motion control.

What can you expect?

7 October 2025 | 9:30-17:00 | High Tech Campus | Eindhoven

- Inspiring presentations by industry experts

- Answers to your technical questions directly from our engineers

- Practical insights and live demos

- Networking opportunities and fun with fellow professionals

Agenda

- 9:30 - Welcome & registrations

- 10:00 - Expert presentations, demos & netwerking

- 12.15 - Lunch, demos & networking

- 13.00 - Expert presentations, demos & networking

- 15:00 - Closing remarks & takeaways

- 15:30 - Fun evenement, drinks & networking

- 17:00 - End

The following real-world applications and innovations will be featured

Higher power density: toward smarter, more integrated motion systems

Presented by Simone Pedrazzi, Applications Engineering Manager at Elmo Motion Control

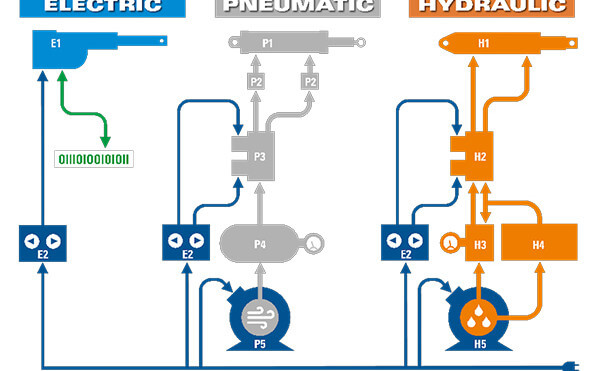

In motion control, the emphasis is shifting from maximizing absolute power to optimizing power density as systems are required to be more compact, efficient, and intelligent.

This session will explore how emerging semiconductor technologies and advanced thermal management strategies are enabling higher power densities in motion drives. We’ll examine how these developments contribute to improved system responsiveness, reduced energy consumption, and enhanced reliability—key factors in modern automation environments.

Impulse Printing: micro-electronics production with high-speed high-precision motion control

Presented by Fabien Bruning, Co-Founder & CTO of FononTech

FononTech will discuss their Impulse Printing technology for advanced chip packaging. Impulse Printing uses rapid parallel heating technology to place materials without touching the surface. This allows for very accurate and quick printing: the fastest 3D interconnect in the world.

For the required overlay performance, real-time high-precision motion control is required. The result is a flexible and scalable platform that helps manufacturers print faster, more accurately, and with lower costs.

Advances in motor technology - Compact motion control with independent linear synchronous motors

Presented by Motor Power Company

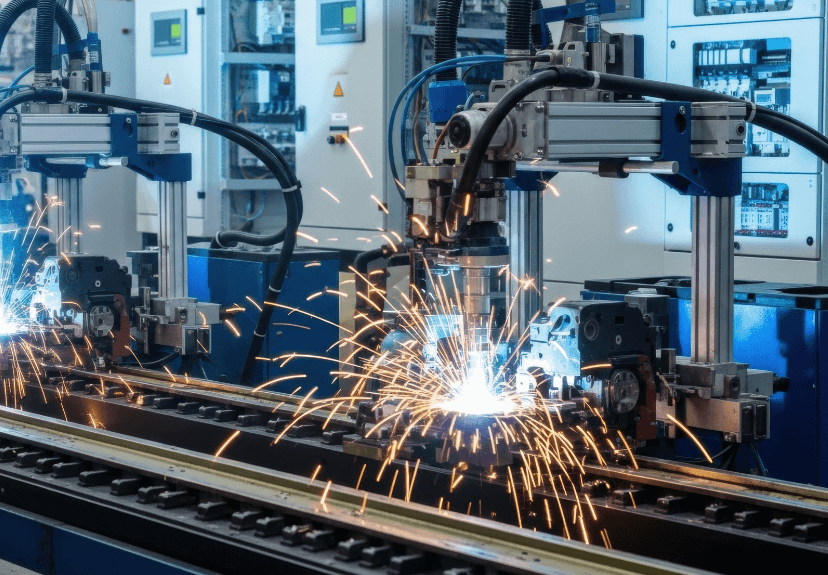

Independent linear synchronous motor (ILSM) technology enables precise, high-speed motion through direct drive, eliminating belts, screws, and gears. This results in accurate, backlash-free movement, reduced mechanical complexity, and lower maintenance requirements.

Furthermore, discover the multipole architecture which enables shorter designs while maintaining high power density, efficiency and speed. A 10-pole servomotor will be showed that is 30% more compact than previous models, ideal for space contrained application.

Functional Safety - a structural shift in system design

Presented by Simone Pedrazzi, Applications Engineering Manager at Elmo Motion Control

As automation systems grow in complexity, functional safety is no longer an add-on but a core design principle. Integrating safety directly into drive technology is transforming system architectures—from modular, isolated components to cohesive, safety-integrated platforms.

This presentation will discuss how embedding safety functions at the drive level impacts system design, enabling tighter integration between motion, control, and safety. The result is a more robust, maintainable, and collaborative automation environment.

Don't miss the Eltrex Motion Innovation Day 2025!

Haven't registered yet? Register using the button below!

Our engineers look forward to welcoming you in person on 7 October!

Feel free to contact us. You can reach us by phone at +31 (0)76 789 00 30 or +32 (0)3 328 07 60. You can also fill in the contact form. We will process your enquiry as soon as possible.