The Shift to Electric

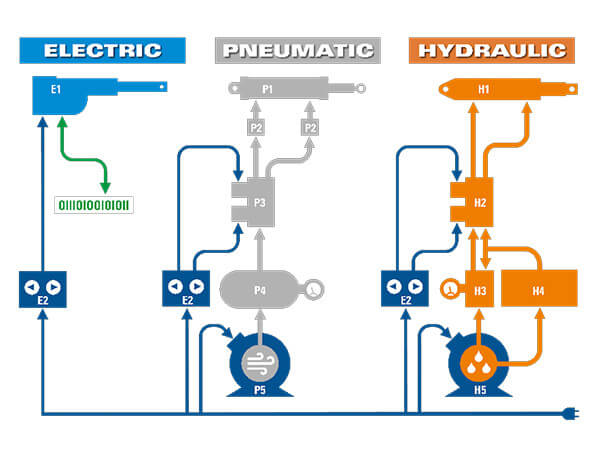

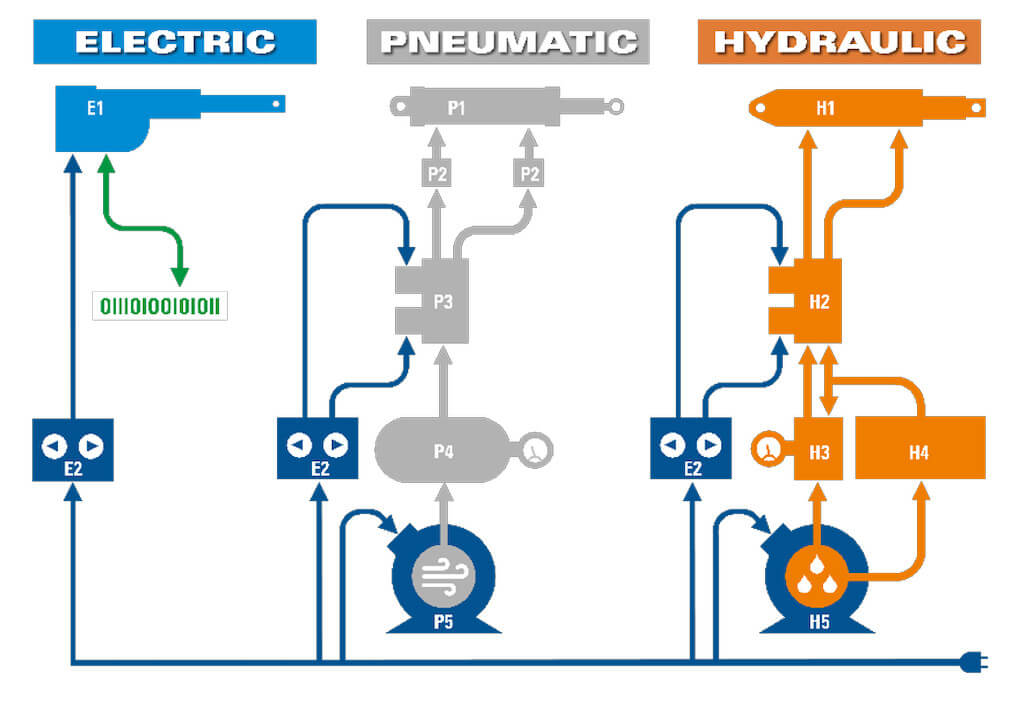

Linear motion is essential in nearly every machine — from seat adjustments in cars to XYZ positioning systems in industrial production. What these applications have in common is the need to move an object in a straight line with speed, force, and precision. This is achieved using a linear drive: hydraulic, pneumatic, or electromechanical.

Hydraulic, pneumatic or electromechanical: What’s right for your application?

Each technology has its own strengths. Hydraulics remain indispensable where extremely high forces are needed — think heavy lifting equipment, large bridges, or sea locks. Pneumatics, in turn, are crucial in environments where explosion-proof operation is vital, such as in the petrochemical industry. However, electromechanical systems are increasingly taking the lead due to their advantages in efficiency, maintenance, controllability, and sustainability — especially in applications where precision and energy management are key.

Less waste, more efficiency

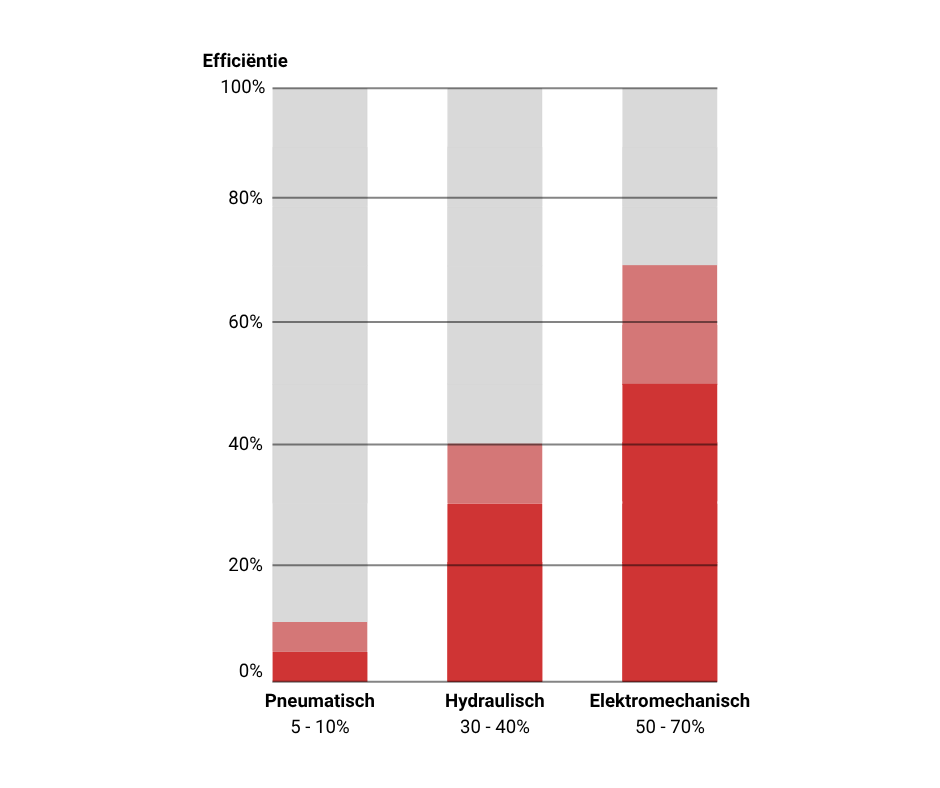

Many industrial systems still rely on compressed air or oil-based solutions. But those methods are often energy-inefficient:

-

Pneumatic systems typically operate at only 5–10% efficiency. Air losses after use and leaks contribute to significant waste.

-

Hydraulic systems perform slightly better, with efficiencies between 30–40%. Still, they require continuously running pumps and lose a portion of their energy through heat.

-

Electromechanical systems, by contrast, achieve efficiencies of 50–70%, deliver power on demand, and can even recover energy in some cases.

For companies looking to reduce energy costs and shrink their environmental footprint, this is a meaningful step forward.

From high-maintenance to maintenance-free

Anyone working with hydraulics or pneumatics knows how maintenance-intensive these systems can be: checking hoses, replacing oil, lubrication, moisture control, and leak detection are all part of the routine. Electromechanical actuators, however, are often designed to be low-maintenance — or even maintenance-free. Built-in diagnostics also make it easier to detect and resolve issues, reducing downtime, preventing unexpected failures, and lowering the total cost of ownership (TCO).

Greater control and precision

Another major advantage of electromechanical systems is controllability. Pneumatics are often limited to simple end positions, while hydraulics require external feedback mechanisms. Electromechanics, on the other hand, offer:

-

Real-time feedback on position, speed, and force

-

Easy synchronization of multiple actuators

-

Full programmability

In applications where accuracy, repeatability, and flexibility are essential — such as food processing, precision agriculture, or automation — this makes a world of difference.

Sustainable, quiet, and clean

Hydraulic leaks don’t just reduce efficiency — they also pose environmental and safety risks. Dirt buildup, product or workspace contamination, and noise pollution are all familiar challenges. Electromechanical systems eliminate many of these concerns thanks to their oil-free and quiet operation. This makes the technology suitable for a wide range of applications, including agri-food, intralogistics, harsh environments, and medical equipment.

Conclusion: the logical choice for modern machinery

For machine builders focused on efficiency, sustainability, and reliability, switching to electromechanical drives is no longer experimental — it's the next logical step. They reduce operating costs, simplify maintenance, and offer a level of control that’s hard to achieve with air or oil.

In short: Choosing electromechanics means choosing control, efficiency, and future-proof design.

Feel free to contact us. You can reach us by phone at +31 (0)76 789 00 30 or +32 (0)3 328 07 60. You can also fill in the contact form. We will process your enquiry as soon as possible.