Get moving with the first collaborative 7th axis

Thomson launched its Movotrak™ Cobot Transfer Unit (CTU), a pioneering collaborative 7th axis designed to enhance the capabilities of collaborative robots (cobots) by extending their operational range and flexibility.

The Thomson Movotrak CTU is a plug-and-play system with up to 10 meters of horizontal operating range, which can help boost productivity for various robotic functions. The collision detection settings provide groundbreaking programming and control benefits. With flexible mounting options, it’s compatible with the largest sized cobots on the market.

Features & Benefits

- User-adjustable collision detection settings allow users to set the sensitivity of the 7th axis per the application requirements.

- 7th axis Freedrive mode allows hand-driven movements to set linear waypoints during programming.

- Dual-linear-unit design delivers maximum moment load and stiffness, even when the cobot arm is fully extended.

- Flexible mounting options (horizontal, inverted, wall-mounted) allow users to optimize their work spaces.

What can a 7th axis do for your productivity?

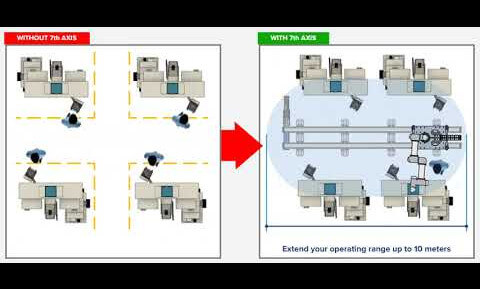

Workplace with and without Movotrak™ CTU

Without 7th axis:

- Space required for aisles between stations

- Potential for workers collisions/ injuries

- Limited reach by workers

- Significant downtime due to shift changes, breaks and overall slower peace of work

- Potentially long learning curve

With 7th axis:

- No aisles required; saves space

- Safer work area

- Extended work area (up to 10 meters)

- 24/7 operations

- Consistent/ reliable quality of work

- Simple installation

- Simple programming

The Movotrak™ CTU is ideal for various industrial applications, including: machine tending, material handling, large-scale welding, soldering, sanding and dispensing and large part testing and inspection.

Feel free to contact us. You can reach us by phone at +31 (0)76 789 00 30 or +32 (0)3 328 07 60. You can also fill in the contact form. We will process your enquiry as soon as possible.