Drives & controllers

Due to significant developments in the field of drives & controllers in recent years, the number of variations and functionalities of drives and controllers has increased enormously. As a result, making a selection is not always easy or straightforward.

Finding the best servo drive and controller for a motion control application

When selecting the right drive and controller for a motion control application, many aspects come into play. Not only the correct motor compatibility but also the requirements of the overarching application and the environment in which it must operate are equally important. Lastly, the price is, of course, also important in the selection process.

Compatibility of the servo drive with the chosen motor

To find a drive that is compatible with the chosen motor, it is necessary to look beyond just the required motor current and motor voltage. The required motor commutation and selection of a motor feedback system are also important. A drive is not always compatible with every feedback protocol. Each protocol has its own advantages and disadvantages. It is important to timely consider which protocol best fits the needs of the application and accordingly select the right type of drive and motor feedback.

The best servo drive for an application

In the application field, other factors are important. A mobile application often requires a drive with a very compact form factor, capable of operating with high efficiency at a low DC battery voltage. This is in contrast to traditional panel drives with a fixed line voltage. When a drive or controller requires a connection to an overarching control system, there are multiple communication protocol options to choose from. Here too, not every drive comes standard with every communication protocol, and it is important to carefully consider which protocol best fits the application and which Drive or Controller is best suited for it.

The importance of the environment of the servo drive - conditioned environment or harsh environment

It is also important to consider the environment in which the drive or controller must operate. Standard drives are often only suitable for conditioned spaces. When conditions are different, there are also drives and controllers for harsh-environment applications, such as in aerospace or deep-sea applications. These are resistant to high temperature, pressure, vibrations, or humidity. It is important to ensure that the respective drive or controller has the appropriate certification or approval required for such conditions.

The role of functional safety

Functional safety is also a frequently seen application requirement nowadays, within the integration of a Drive or Controller in the application. Whether a drive has this functionality and to what level of safety category it is certified is important to ultimately achieve a safe machine.

The development process, the development environment, and the commissioning of the servo drive and application

Lastly, there are aspects related to the development environment and commissioning of drives and controllers. Standard assembled drives and controllers that can be quickly made operational independently through quick-setup and auto-tuning, to complex systems with individual parameter mapping, and the design of custom control algorithms and programming code in a drive or controller under the guidance of full custom engineering, are among the possibilities.

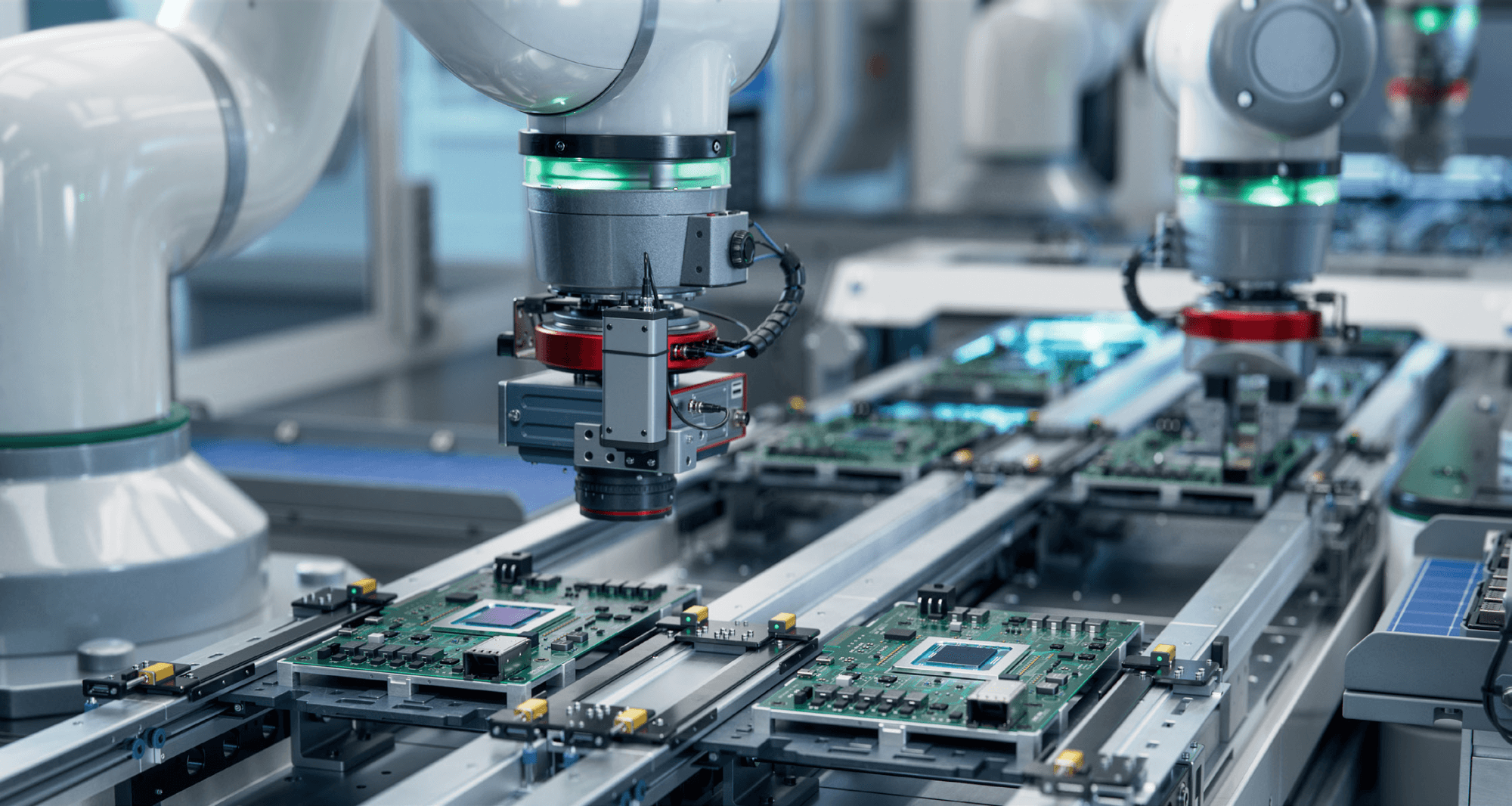

Flexibility, freedom of choice, and quick results for your motion control application thanks to expertise and a wide range of servo drives

From replacing a single drive in an existing application, to designing a completely new motion control system from scratch. From budget-friendly stepper solutions to complex full closed-loop servo motion with multiple synchronized axes at high speed or extreme precision. Eltrex Motion has the right range and expertise in drives and controllers to offer the best possible solution.

Additionally, Eltex has the capability to build or customize drives and controllers to your specific requirements

Feel free to contact us. You can reach us by phone at +31 (0)76 789 00 30 or +32 (0)3 328 07 60. You can also fill in the contact form. We will process your enquiry as soon as possible.