Small, powerful servo drives for advanced motion control applications

Whitepaper

This is a summary of the whitepaper Driving Robotics and Embedded Motion Applications With Next-generation Servo Technology van Copley Controls. Download the complete whitepaper for all information.

Introduction

Er is een groeiende behoefte aan kleine, krachtige servo aandrijvingen voor geavanceerde motion control-toepassingen. Deze servo aandrijvingen zijn essentieel voor veel moderne machines, waarin de beschikbare ruimte beperkt is en waar de aandrijving vaak direct op de motor of binnen een robotgewrichten gemonteerd is.

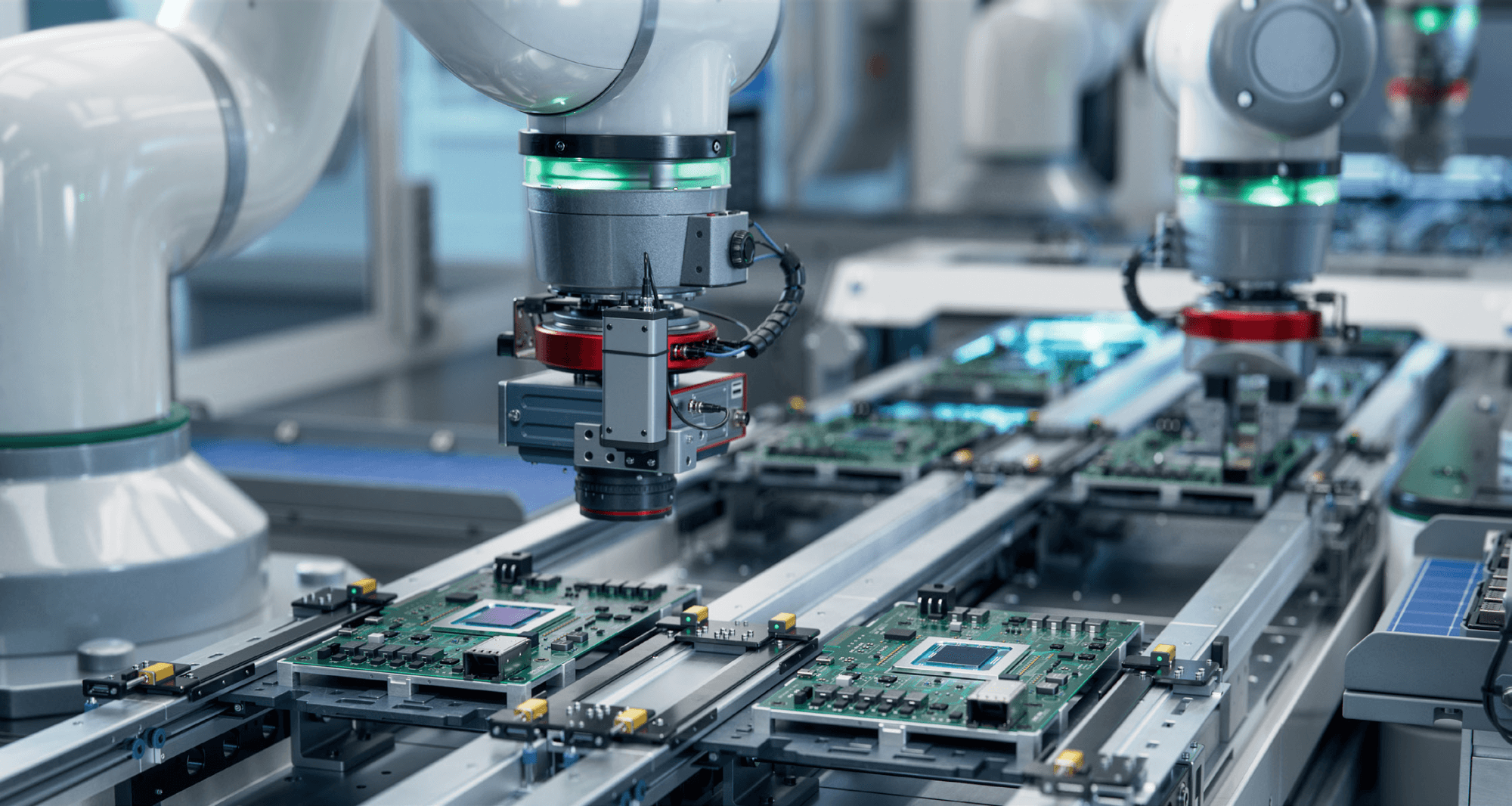

There is a growing need for small, powerful servo drives for advanced motion control applications. These servo drives are essential for many modern machines, where the available space is limited and the drive is often mounted directly on the motor or within robot joints.

In several applications, compact servo drives are crucial:

- Healthcare: for advanced surgical and diagnostic procedures

- Semiconductor manufacturing: high precision in handling fragile components

- Logistics: efficient navigation of mobile robots in warehouses

- Aerospace, laboratory automation, biomedical equipment: handling and transporting objects with great precision

Requirements that servo drives must meet include:

- High accuracy and repeatability to ensure precise movements.

- Excellent dynamic performance, including smooth motion profiles, fast response times, and precise speed and torque control.

- Support for real-time communication protocols (such as EtherCAT) for reliable communication between drive and control system

- Compact size with sufficient power: despite their small size, they must be powerful enough to move robot parts reliably and efficiently.

Stay cool

Designing miniature servo drives presents significant thermal management challenges due to the reduced surface area for heat dissipation. There are several strategies to address these challenges:

- Circuit materials - copper alloy substrates: for example, the Copley Nano drive uses a 4-layer stacked PCB with a copper alloy substrate (TClad). This results in a threefold improvement in thermal conductivity compared to traditional aluminum substrates.

- Custom-designed pins: these pins are smaller than standard connectors and are designed to dissipate heat from the drive, improving heat dissipation capacity.

- Dynamic Gate Drive Tuning: gate driver IC and MOSFET: the selection of compact, high-output current gate driver ICs and small, low-thermal resistance MOSFETs is crucial. Dynamic gate drive tuning optimizes the timing between the operation of power devices to minimize power consumption and meet electromagnetic compatibility (EMC) requirements.

- Current measurement: Ultra-low resistances: these allow accurate current measurement with minimal heat development, further reducing heat dissipation

Thermal management strategies

The smallest, most powerful servo drives apply various strategies to minimize heat buildup:

- Construction and layout: the overall construction and layout of power components on the circuit board are optimized for thermal management.

- Firmware adjustments: features such as bus clamping can reduce switching losses by up to 33%.

Power consumption

The Nano series from Copley Controls is an example of servo drives that combine the right power density with thermal management. Features include:

- Compact format with a 35x30x23.4 mm footprint.

- High power density and efficiency: input voltage from 9 to 180V DC combined with 35A continuous current and 70A peak current.

- EtherCAT or CANopen communication protocols for supporting real-time data exchange.

- Advanced thermal management through the integration of multiple design principles for effective heat dissipation.

- Safe Torque Off (STO) capability: With SIL 3, Category 3, PLe compliance.

- Digital inputs and outputs: 6 digital inputs and 4 digital outputs.

- Analog input: One ±10-volt (V) 12-bit analog input.

- Encoder support: BiSS-C unidirectional, SSI absolute encoders, CSR Resolver, and digital incremental encoder.

- Frequency analysis tools for advanced diagnostics.

- Dual encoder feedback support for improved precision.

- Advanced filters: 32-bit floating point filters and multiple advanced filters.

(Download the full whitepaper to see the power consumption of the NES-090-70 and NES-18-10 from both the PWM power and the total consumption of PWM and V-logic power. Nano Series)

Conclusion

The success of compact servo drives depends on a combination of multiple design principles to achieve high power density, efficiency, and effective thermal management. These drives are suitable for a wide range of applications in robotics and embedded motion control, and represent the latest generation of motion control technology.

Feel free to contact us. You can reach us by phone at +31 (0)76 789 00 30 or +32 (0)3 328 07 60. You can also fill in the contact form. We will process your enquiry as soon as possible.