Read more about Agri Automation? Enter your e-mail address here and you will receive the PDF.

How Disruptive Mobile Robots Powered by Elmo Servo Drives Have Revolutionized Warehousing

A decade or two ago, customers who bought goods online would wait five to 10 days to receive their orders, unless they paid an extravagant fee for express delivery. Today, e-commerce models have trained consumers to expect instant gratification. They can download books, music, movies, and podcasts with the touch of the screen. Even when they buy physical products online, they still expect to receive their packages in a fraction of the time it took previously. To reliably offer rapid delivery at minimal pricing, an Asian e-commerce giant launched an initiative to replace its conventional shipping centers with fully automated, unmanned sorting facilities. The success of the venture hinged on a fleet of low-profile mobile powered by compact, efficient, high-performance servo drives from Elmo Motion Control.

Compact Mobile Robots

The retailer sells a vast array of goods ranging from seafood to shampoo, T-shirts to tablets, and much, much more. To meet customer demand, the sorting centers need to handle up to 9000 parcels per hour. The solution was to place the inventory in pods that are transported around the facility using mobile robots. The pods are elevated by metal legs. The robots roll underneath and rise vertically until the legs are no longer in contact with the floor (see figure). Now, the robot can transport the pod to a designated packaging station, navigating using barcodes laid out on the floor of the logistics center.

The warehousing environment presents a number of challenges. The robots need to have a low profile so that they can fit under the pods. They also need to be as compact as possible so that hundreds, or even thousands of them can move around the facility without colliding. At the same time, they must be able to lift heavy loads¾while one pod may contain tissues, another might hold 300-kg bags of dog food. Finally, the robots need to provide the longest possible lifetime per charge. After all, the warehouse can’t respond to customer orders if all of the robots are in their charging stations.

High Power Density

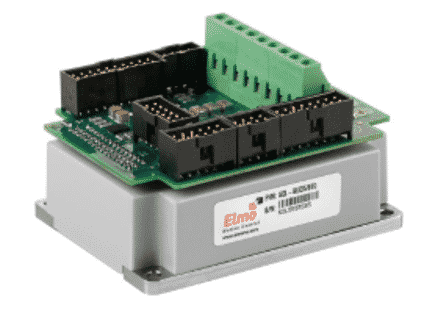

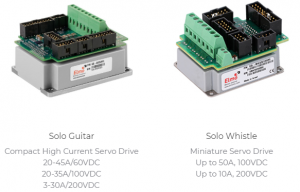

The robots are propelled by two traction wheels. They also have a vertical lift capability to raise the pods. To power the two traction wheels, the engineering team specified a pair of 750 W brushless servo motors. Given the space limitations of the robots, the team needed drives with the highest possible power density. They found the solution in Elmo’s Solo Guitar drives. Solo Guitar drives provide up to 4.8 kW of continuous power or 5.4 kW of peak power, in a package measuring just 46.7 mm x 61 mm x 80 mm.

The third axis in the system is the rotating lift, which is powered by a 100 W brush motor capable of lifting up to 300 kg. For this axis, the team chose an Elmo Solo Whistle drive, which delivers 2 kW of continuous power as well as peak power, in a 58.25 mm x 46.5 mm x 28.5 mm package. The Solo Whistle drives receive pulse/direction signals directly from the customer’s controller.

High Power Density

The robots are propelled by two traction wheels. They also have a vertical lift capability to raise the pods. To power the two traction wheels, the engineering team specified a pair of 750 W brushless servo motors. Given the space limitations of the robots, the team needed drives with the highest possible power density. They found the solution in Elmo’s Solo Guitar drives. Solo Guitar drives provide up to 4.8 kW of continuous power or 5.4 kW of peak power, in a package measuring just 46.7 mm x 61 mm x 80 mm.

The third axis in the system is the rotating lift, which is powered by a 100 W brush motor capable of lifting up to 300 kg. For this axis, the team chose an Elmo Solo Whistle drive, which delivers 2 kW of continuous power as well as peak power, in a 58.25 mm x 46.5 mm x 28.5 mm package. The Solo Whistle drives receive pulse/direction signals directly from the customer’s controller.

High Efficiency Drives

The per-charge operating lifetime of a mobile robot depends heavily on the efficiency of its electrical components. The more efficient the servo drives, the longer the robots can operate between charges. The Solo Guitar drives are over 97% efficient, while Solo Whistle drives are over 99% efficient. As a result, they are ideal for handling the limited power supply and increasing the overall duty cycle of the robot.

The power characteristics of batteries vary throughout each discharge cycle, as well as over the total lifetime of the battery. Solo Guitar drives are designed to tolerate voltage swings from 46 to 195 VDC, while Solo Whistle drives can handle voltage swings from 12 to 95 VDC for the 100V and 24 to 195 VDC for the 200V. As a result, they minimize nuisance faults to maintain continuous operation.

Minimizing Jitter And Latency

In order to steer the robots, the traction axes must be precisely synchronized. The design is based on a master-slave architecture with the primary axis receiving its commands from a customer-designed controller via an analog +/-10V command. For feedback, these axes use a combination of Hall-effect sensors and a 1000-line incremental optical encoder. The engineering team initially planned to use analog current following for synchronization. The Elmo drives provided a more effective alternative.

Elmo drives can receive or generate a wide variety of reference commands: analog +/-10V, pulse-width modulation (PWM), pulse/direction, encoder follower, ECAM, user program, and direct communication. In the case of the warehousing robots, the drives were operated in PWM mode. Elmo drives allow PWM commands to be used as either current reference commands or speed reference commands, all which can be implemented simply with Elmo’s readily available tools. Now, the robot traction system could send a high-speed PWM command from the primary traction axis to the secondary traction axis. The PWM synchronization to the slave is an ideal way to create axis following with minimal jitter or latency delays. The PWM sync proved to be much more successful than the initial analog current following concept.

So far, the project is working well. After two months of testing, the drives’ performance and overall functionality has met requirements. In the next generation of robots, communications will be routed over a CANopen signal rather than an analog +/-10V signal. With the addition of Elmo’s full CANopen support, flexibility in drive programming, and a wide voltage range, the retailer locked in on the ideal servo drive solution for its growing fleet of warehouse robots.

The initiative is moving into production mode, with an expected 1000 robots to be made over the next three to four years for the planned 10 unmanned sorting centers. The e-commerce giant intends to continue investing in innovative technologies to provide highly efficient, low-cost, intelligent supply-chain solutions.